A Comprehensive Case Study of Boiler Materials for the Pulp and Paper Industry

The pulp and paper industry relies heavily on boilers to generate steam for various processes, including papermaking, pulp digestion, and power generation. The performance and durability of these boilers are crucial for the efficient operation of paper mills. The selection of appropriate boiler materials is a critical aspect that impacts the overall lifespan, operating costs, and safety of the boiler.

5 out of 5

| Language | : | English |

| File size | : | 1566 KB |

| Text-to-Speech | : | Enabled |

| Print length | : | 60 pages |

| Lending | : | Enabled |

This case study presents a comprehensive analysis of the performance of different boiler materials commonly used in the pulp and paper industry. By examining their corrosion resistance, heat resistance, and mechanical properties, paper mills can make informed decisions when designing, installing, and maintaining their boiler systems.

Boiler Materials for the Pulp and Paper Industry

The pulp and paper industry operates in a highly corrosive environment characterized by the presence of sulfur compounds, ash, and other chemicals. As a result, boiler materials must possess exceptional corrosion resistance to withstand these harsh conditions. The commonly used boiler materials in this industry include:

- Carbon Steel: Low-cost and widely available material, but susceptible to corrosion in acidic environments.

- Stainless Steel: Offers better corrosion resistance than carbon steel, particularly against sulfuric acid, but more expensive.

- Nickel Alloys: High corrosion resistance and strength, but very expensive and subject to embrittlement.

- Titanium Alloys: Excellent corrosion resistance and lightweight, but the high cost and embrittlement susceptibility limit their use.

Performance Analysis of Boiler Materials

To assess the performance of these boiler materials, a detailed study was conducted in a real-world paper mill environment. Boilers were constructed using each material, and their performance was monitored over an extended period. The following parameters were evaluated:

- Corrosion Resistance: Weight loss measurements were used to quantify the corrosion rate of each material.

- Heat Resistance: Temperature measurements were taken at critical points in the boiler to assess the material's ability to withstand high temperatures.

- Mechanical Properties: Tensile strength, yield strength, and hardness were measured to evaluate the material's ability to withstand stresses and deformation.

Results and Discussion

The study revealed significant differences in the performance of the evaluated boiler materials:

- Corrosion Resistance: Stainless steel exhibited the highest corrosion resistance, followed by nickel alloys and titanium alloys. Carbon steel had the lowest corrosion resistance.

- Heat Resistance: All materials maintained their strength and integrity at high temperatures. However, stainless steel showed slightly lower creep strength than nickel alloys and titanium alloys.

- Mechanical Properties: Nickel alloys and titanium alloys had superior mechanical properties, including higher tensile strength and yield strength. Carbon steel had the lowest mechanical strength.

Selection Criteria for Boiler Materials

Based on the performance analysis, paper mills can select the most suitable boiler material for their specific operating conditions by considering the following criteria:

- Corrosion Environment: The severity of the corrosive environment should guide the selection of materials with appropriate corrosion resistance.

- Temperature Requirements: The maximum operating temperature should be considered to ensure that the material can withstand the stresses without losing strength.

- Cost Considerations: The cost of the material should be balanced against its expected lifespan and maintenance requirements.

- Embrittlement Concerns: Materials susceptible to embrittlement should be avoided for applications where sudden failure could be catastrophic.

Maintenance and Inspection Practices

Regular maintenance and inspection are crucial for ensuring the longevity of boiler materials. Proper maintenance practices, such as water treatment, corrosion monitoring, and scheduled inspections, can extend the lifespan of the boiler and prevent unexpected failures.

- Water Treatment: Proper water treatment prevents scale formation and reduces corrosion.

- Corrosion Monitoring: Regular corrosion monitoring allows early detection of corrosion issues.

- Inspections: Scheduled inspections identify areas of concern and enable prompt repairs.

The selection of appropriate boiler materials is essential for the efficient and reliable operation of boilers in the pulp and paper industry. By understanding the performance characteristics of different materials, paper mills can make informed decisions that optimize corrosion resistance, heat resistance, and mechanical properties. Regular maintenance and inspection practices further enhance the lifespan and safety of boiler systems. This case study provides valuable insights for paper mills to optimize their boiler operations and minimize downtime.

5 out of 5

| Language | : | English |

| File size | : | 1566 KB |

| Text-to-Speech | : | Enabled |

| Print length | : | 60 pages |

| Lending | : | Enabled |

Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

Top Book

Top Book Novel

Novel Fiction

Fiction Nonfiction

Nonfiction Literature

Literature Paperback

Paperback Hardcover

Hardcover E-book

E-book Audiobook

Audiobook Bestseller

Bestseller Classic

Classic Mystery

Mystery Thriller

Thriller Romance

Romance Fantasy

Fantasy Science Fiction

Science Fiction Biography

Biography Memoir

Memoir Autobiography

Autobiography Poetry

Poetry Drama

Drama Historical Fiction

Historical Fiction Self-help

Self-help Young Adult

Young Adult Childrens Books

Childrens Books Graphic Novel

Graphic Novel Anthology

Anthology Series

Series Encyclopedia

Encyclopedia Reference

Reference Guidebook

Guidebook Textbook

Textbook Workbook

Workbook Journal

Journal Diary

Diary Manuscript

Manuscript Folio

Folio Pulp Fiction

Pulp Fiction Short Stories

Short Stories Fairy Tales

Fairy Tales Fables

Fables Mythology

Mythology Philosophy

Philosophy Religion

Religion Spirituality

Spirituality Essays

Essays Critique

Critique Commentary

Commentary Glossary

Glossary Bibliography

Bibliography Index

Index Table of Contents

Table of Contents Preface

Preface Introduction

Introduction Foreword

Foreword Afterword

Afterword Appendices

Appendices Annotations

Annotations Footnotes

Footnotes Epilogue

Epilogue Prologue

Prologue James Ferloy

James Ferloy Lisa Sabin Wilson

Lisa Sabin Wilson Donald S Passman

Donald S Passman Kennedy Fox

Kennedy Fox Darren Ellwein

Darren Ellwein Olga Tokarczuk

Olga Tokarczuk Kathy Henn

Kathy Henn Charles Dagher

Charles Dagher Eiichiro Oda

Eiichiro Oda John Mccullough

John Mccullough Adam Muller

Adam Muller Actus

Actus Richard Kostelanetz

Richard Kostelanetz R L Medina

R L Medina Robin York

Robin York Brandi Robinson

Brandi Robinson Tim Tate

Tim Tate Lisa Campton

Lisa Campton Jim Lusk

Jim Lusk Steve Hart

Steve Hart

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

Dakota PowellMonth in the Country: A Captivating Russian Drama About Love, Betrayal, and...

Dakota PowellMonth in the Country: A Captivating Russian Drama About Love, Betrayal, and... Brady MitchellFollow ·4.3k

Brady MitchellFollow ·4.3k Deacon BellFollow ·12.6k

Deacon BellFollow ·12.6k Jerry WardFollow ·19.4k

Jerry WardFollow ·19.4k Mark MitchellFollow ·10.9k

Mark MitchellFollow ·10.9k Damon HayesFollow ·11.4k

Damon HayesFollow ·11.4k Eugene ScottFollow ·3.4k

Eugene ScottFollow ·3.4k Clarence BrooksFollow ·10.6k

Clarence BrooksFollow ·10.6k Chinua AchebeFollow ·16.1k

Chinua AchebeFollow ·16.1k

Kelly Blair

Kelly BlairSheppard Lee Written By Himself: A Journey of...

In the realm of...

George Bernard Shaw

George Bernard ShawViper Naga Brides: Unveiling the Enthralling Fantasy...

In the realm of...

Neil Gaiman

Neil GaimanOnce Upon a Hill in Tuscany: A Medieval Short Story

In the heart of medieval...

Preston Simmons

Preston SimmonsBody Bereft: Exploring Loss, Love, and Legacy in Antjie...

A Poetic Requiem for the Lost:...

Percy Bysshe Shelley

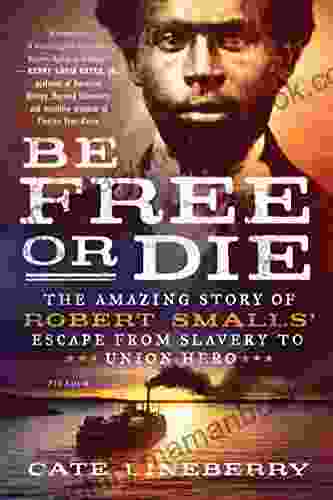

Percy Bysshe ShelleyThe Amazing Story Of Robert Smalls Escape From Slavery To...

The life of Robert Smalls is a testament to...

5 out of 5

| Language | : | English |

| File size | : | 1566 KB |

| Text-to-Speech | : | Enabled |

| Print length | : | 60 pages |

| Lending | : | Enabled |